Diamond Hole

- Home

- About Us

-

CITTI Mesh that supplies you better solutions and the quality wire meshes. This is your one-stop wire mesh solution provider.About CITTI

-

- Products

-

CITTI Mesh deals with the following products: filtering series, fencing series, architectural mesh, engineering materials, livestock, processed, wire materials, others, click to learn more about our major products.More Products

- Architectural Mesh

- Decorative Wire Mesh

- Kinetic Facade

- Cable Architectural Mesh

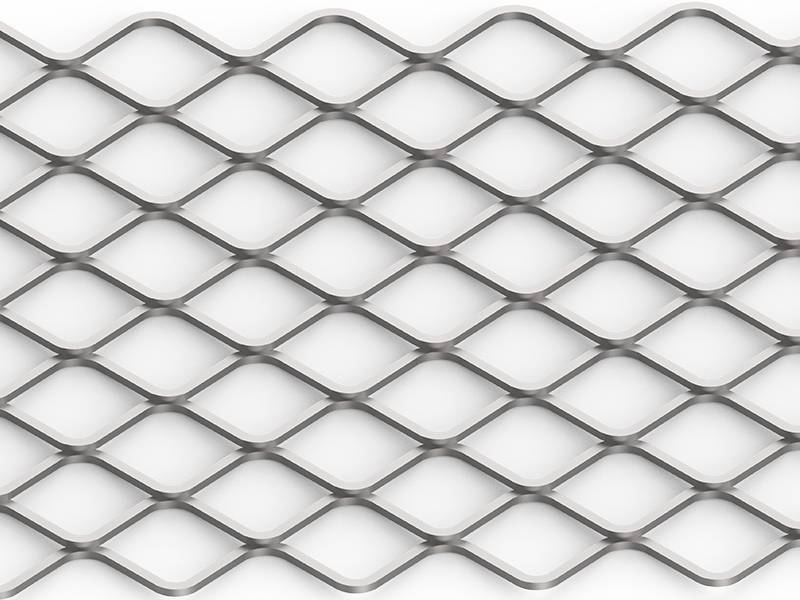

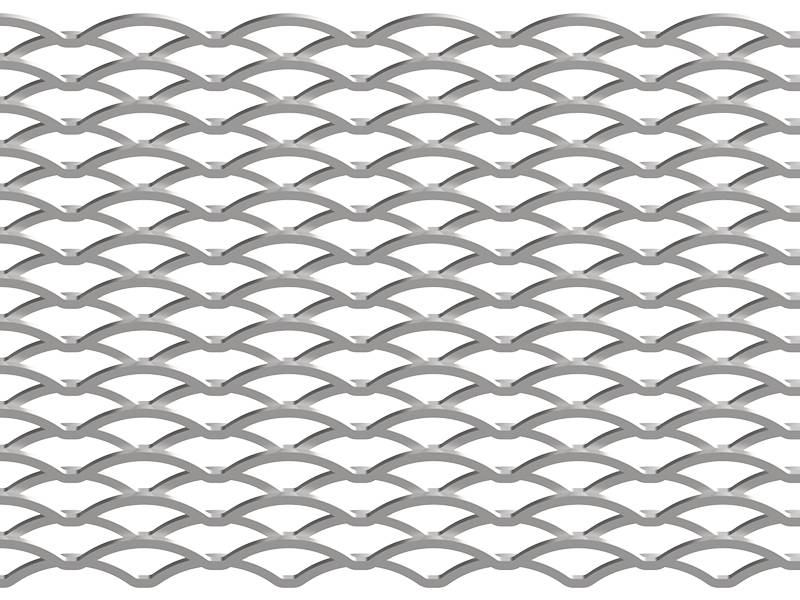

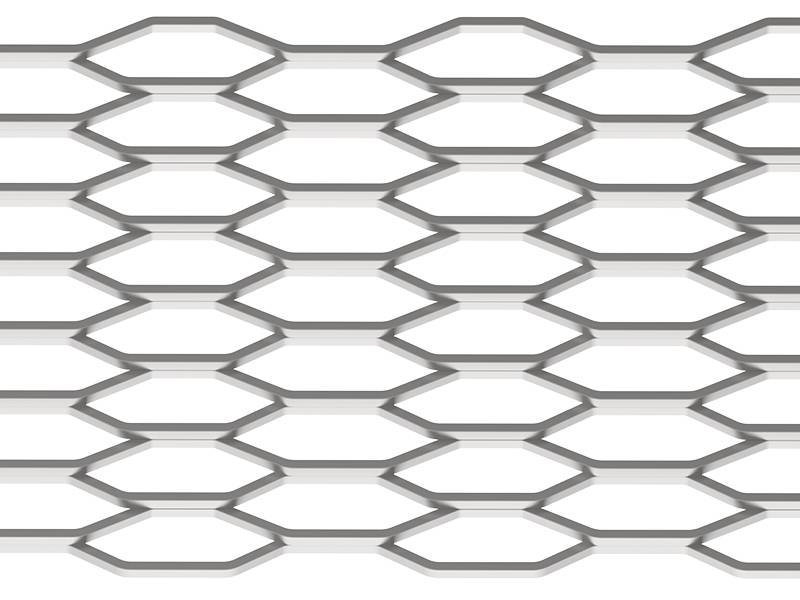

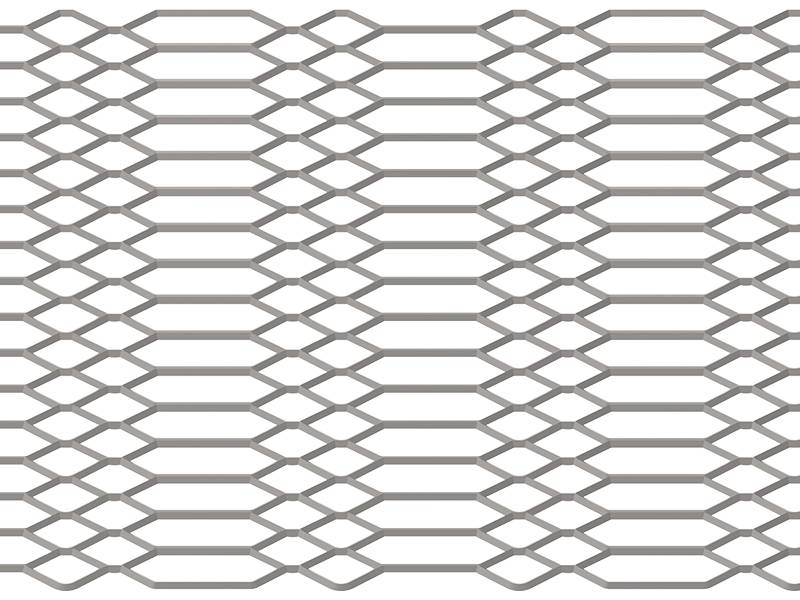

- Architectural Rigid Mesh

- Metal Curtains

- Honeycomb Decorative Mesh

- Laminated Glass Mesh

- Oil Mesh Series

- Materials

- Filtering Series

- Fencing Series

- Engineering Materials

- Livestock

- Processed

- Barbecue Grill

- Metal Conveyor Belt

- Polyester Mesh Belt

- Wire Mesh Strainer

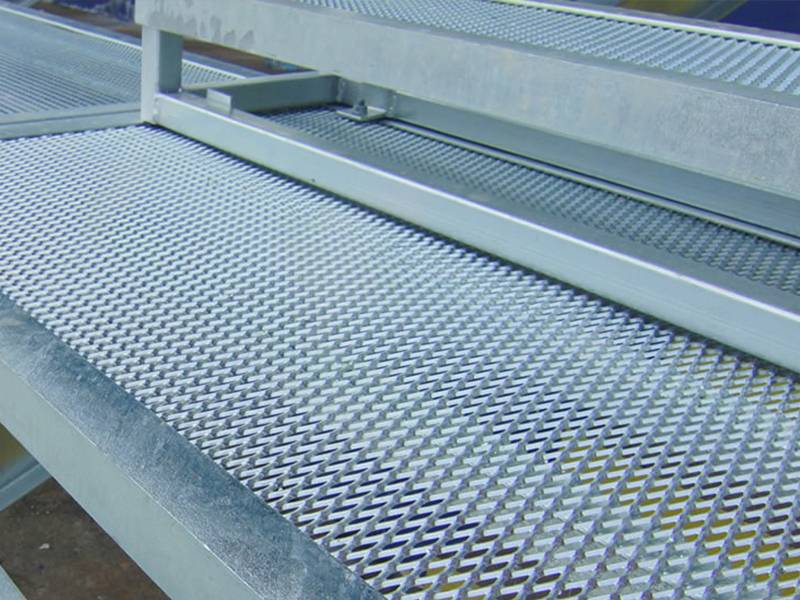

- Self-cleaning screen

- Woven Vibrating Screen Mesh

- Architectural Mesh

-

- Solutions

-

Our products are used every day in the world for safety protection, building and decoration, construction, filtration and screening, desalination and environmental greening. Therefore, it is not surprising that our wide range of products have made us a global market leader.More Solutions

-

- Contact Us